Wednesday, April 30, 2014

The 5th Semi-finalists Start:up 2014: For more efficient welding

When welding materials are thicker than 3 millimeters, it is necessary to prepare a weld edge, which doubles the work, as it is necessary to first weld the edge, remove the weld edge and then fill it with filler material. For this purpose, company Juvar developed coatings that enable effective welding to a thickness of 10 millimeters, with a single pass and without edge preparation. The use of the coating significantly reduces the consumption of filler materials, electricity, shielding gas, reduces welding time by more than a half and the company does not need to invest into new welding equipment. A further advantage of the coating is that it is not harmful to the health of the welder.

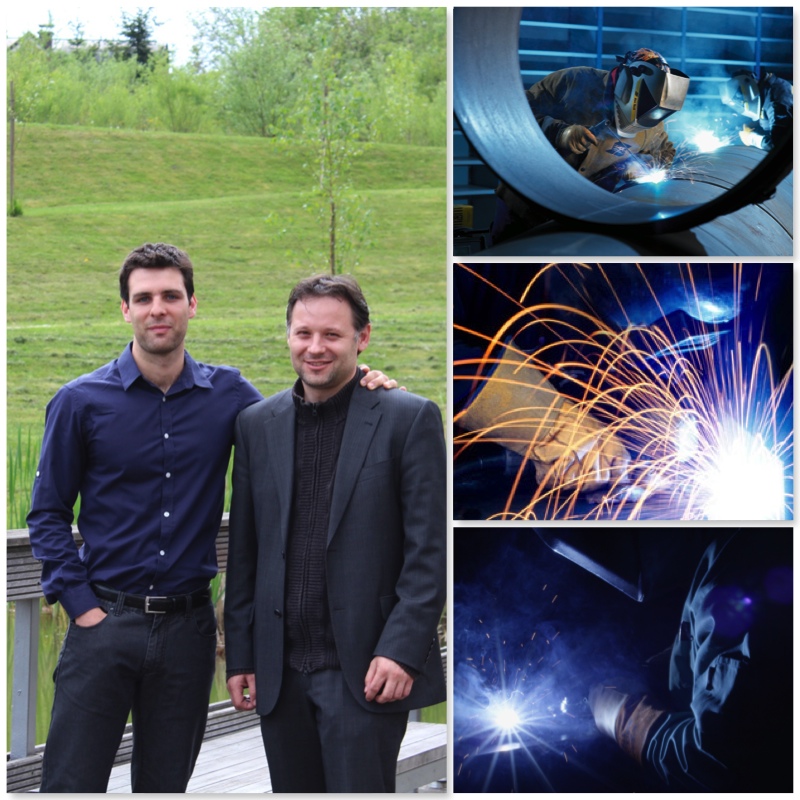

The team of start-up Juvar Ltd. (from left to right: Jan Juvan and Damjan Klobčar PhD)

This year the company completed a two-year development process of the first version of the coating for TIG welding of stainless steel. Next year they will start developing products for other materials, which will be presented at the end of 2016. The company has some competitors on the global market, but their coats contain harmful elements, especially chromium (III) oxide, which is harmful to the respiratory system of the welder.

Coatings are suitable for all businesses that weld steel, titanium, aluminum and other alloys using TIG, laser and MIG methods. This includes welding for the pharmaceutical, food, chemical, ship, aviation and aerospace industry. In the future, they wish to establish a wider distribution network through their distributors and start direct sales to target companies. They also want to participate in the educational process in welding institutes and faculties.

Author: Anja Kodra

The team of start-up Juvar Ltd. (from left to right: Jan Juvan and Damjan Klobčar PhD)

This year the company completed a two-year development process of the first version of the coating for TIG welding of stainless steel. Next year they will start developing products for other materials, which will be presented at the end of 2016. The company has some competitors on the global market, but their coats contain harmful elements, especially chromium (III) oxide, which is harmful to the respiratory system of the welder.

Coatings are suitable for all businesses that weld steel, titanium, aluminum and other alloys using TIG, laser and MIG methods. This includes welding for the pharmaceutical, food, chemical, ship, aviation and aerospace industry. In the future, they wish to establish a wider distribution network through their distributors and start direct sales to target companies. They also want to participate in the educational process in welding institutes and faculties.

Author: Anja Kodra